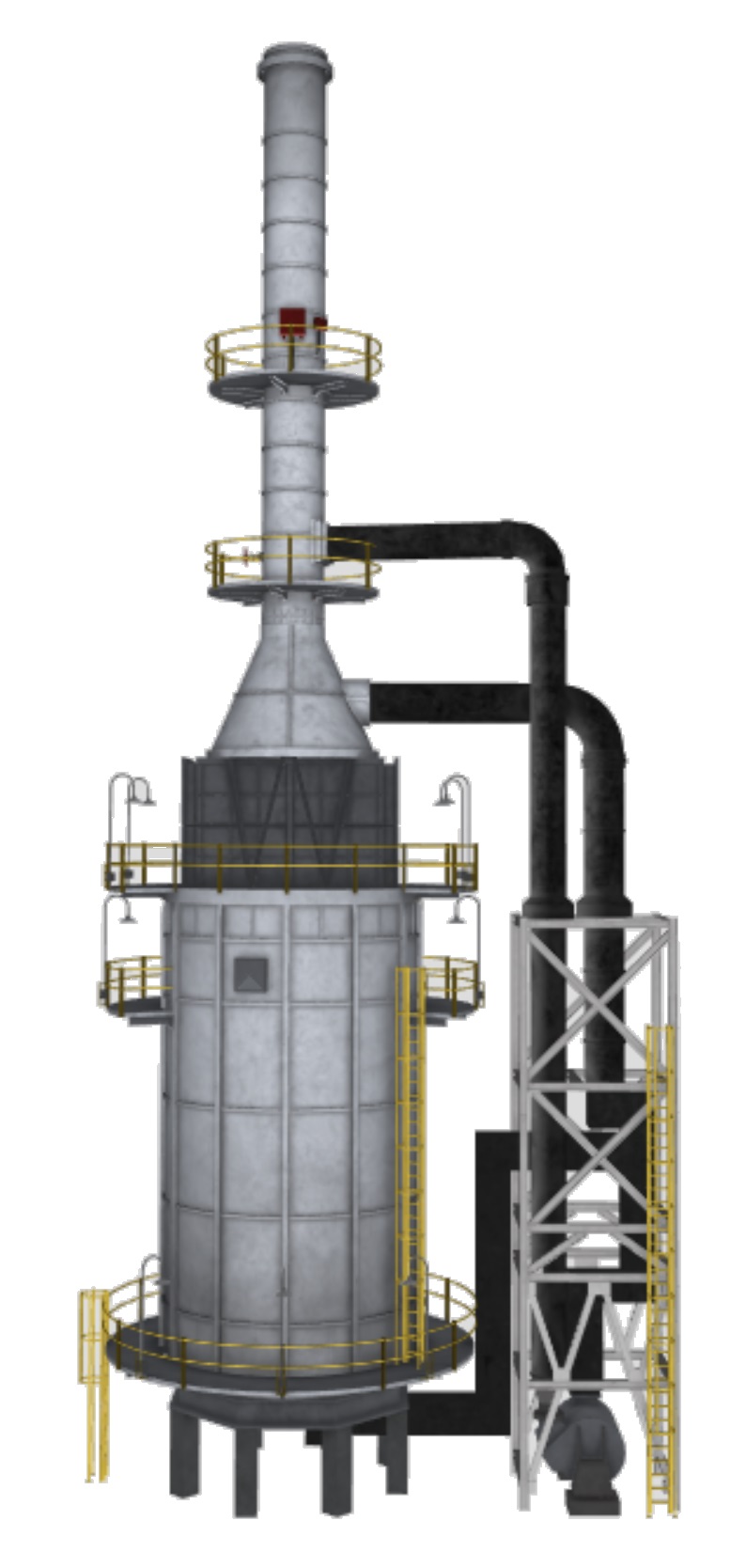

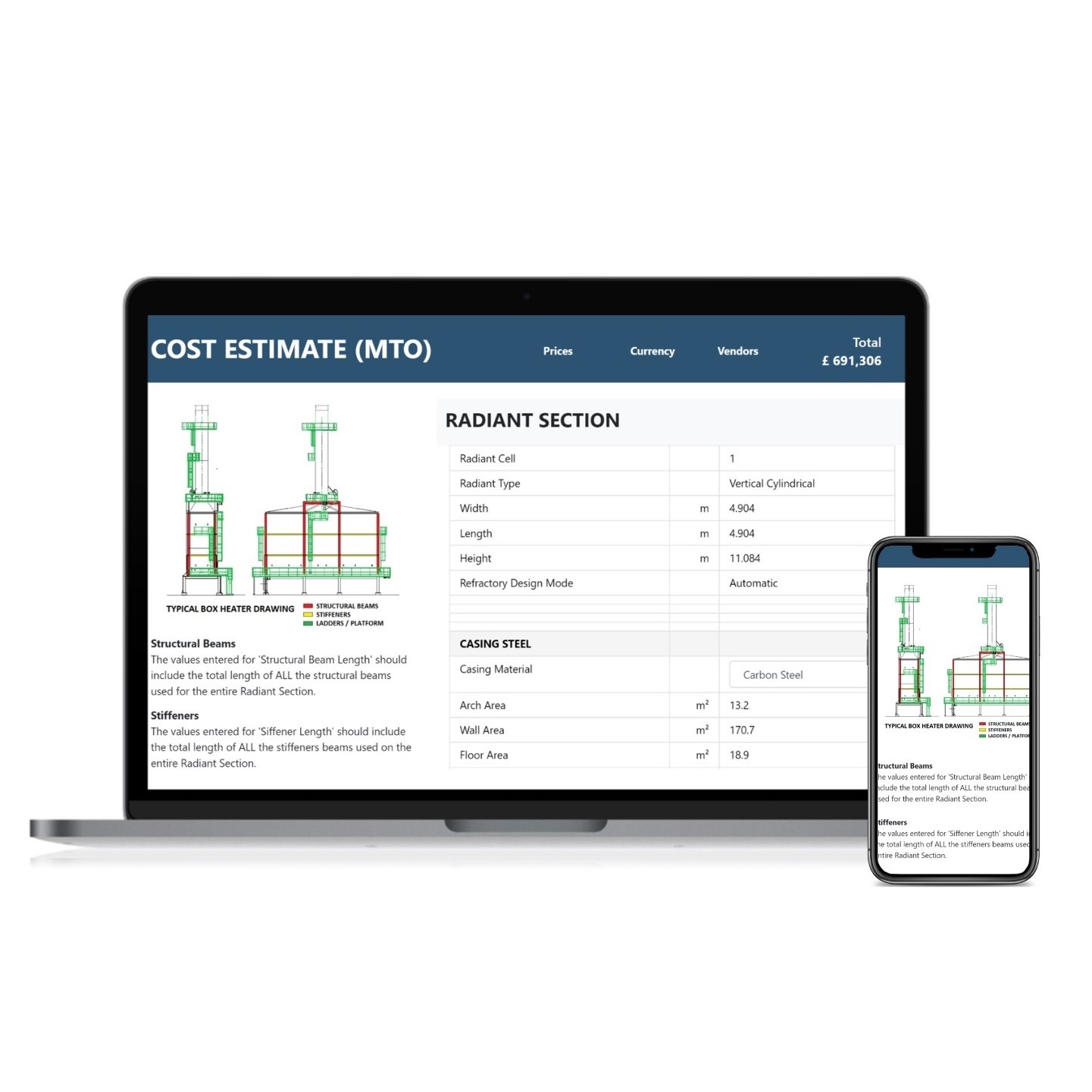

Fired Heater Simulation Technology for EPC, Revamp & Troubleshoot projects

Expert assistance for the success of your Fired Heater & WHRU Projects

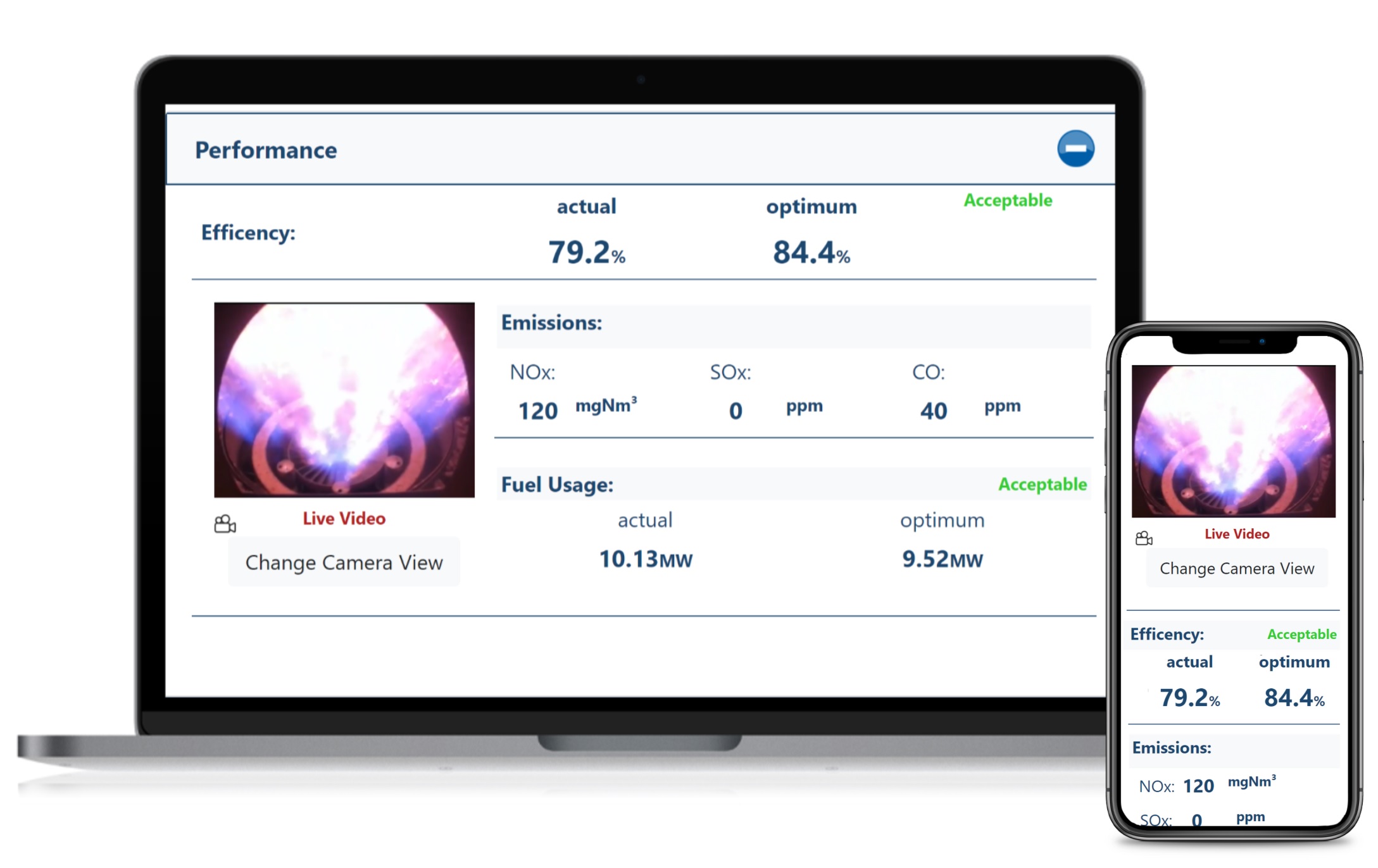

Optimize Fired Heater energy performance without compromising production targets

Groundbreaking technology to simulate fired heater combustion, heat transfer and emissions with incredible detail and accuracy